Vibration Analysis

Vibration Monitoring ensures reliable operations and your rotating equipment is monitored for impending problems or existing defects

VIBRATION APPLICATIONS

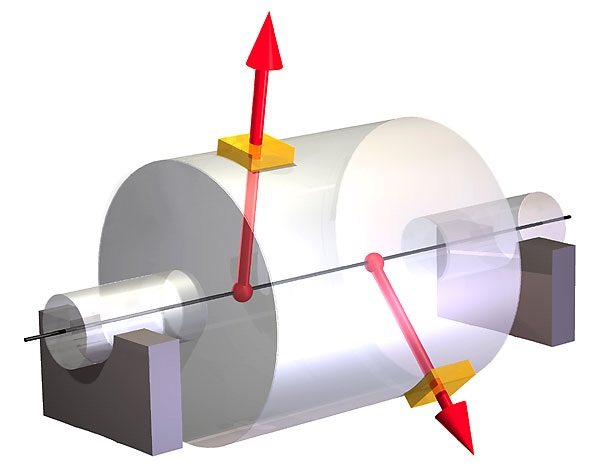

Onsite Balancing

1 & 2-plane site balancing – For static and dynamic

balancing

Benefits: Eliminates the requirements to completely

dismantle and reassemble plant equipment to enable

balancing of machine components

Improves product quality

Reduces downtime, labor and material costs

Can be planned into scheduled short time outages

Centrifugal Pumps Analysis

Cavitation

Pump Flow Pulsation

Bent Pump Shaft

Unbalance of Pump Impeller

Shaft Misalignment

Pump Bearing Problems

Fans Vibration Analysis

Unbalance of Overhung Fans

Unbalance of Center-Hung Fan Wheel

Belt Problems and Drive Misalignment

Air Flow and Air Turbulence Problems

Fan Bent Shaft Condition

Fan Surge Condition

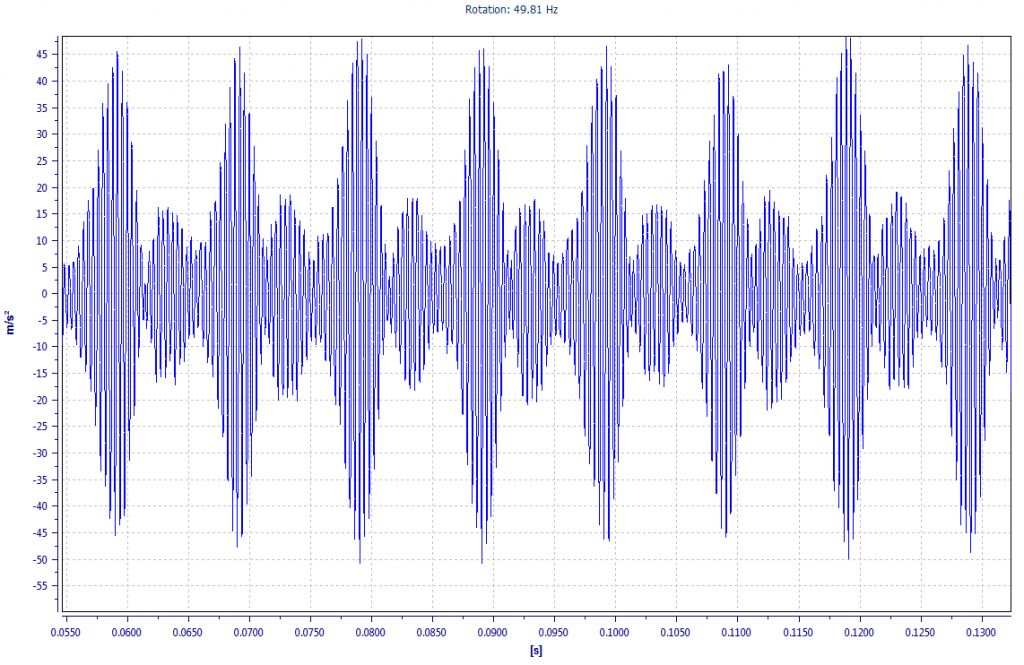

transient vibration

Performing transient vibration analysis testing for rotating machines such as:

– Natural frequency test

– critical speed test

– Run-up/Coast-down test.

N

Vibration

Vibration measurement and analysis survey for rotating equipment based on annual contract or pre request by certified vibration analyst.

- Conducting acceptance test for new/repaired machine.

- Onsite rotor balancing

- Laser alignment for vertical and horizontal rotating machines

- Performing special testing for rotating machines as:

- Natural frequency test

- critical speed test

- Run-up/Coast-down test.

- Training courses

- certification from vibration institute

- Operational modal analysis (OMA) test.

- Machine mode shape in operation – Structural resonance.

- Static equipment and piping mode shape.

Centrifugal Pumps Analysis

- Cavitation

- Pump Flow Pulsation

- Bent Pump Shaft

- Unbalance of Pump Impeller

- Shaft Misalignment

- Pump Bearing Problems

Fans Vibration Analysis

- Unbalance of Overhung Fans

- Unbalance of Center-Hung Fan Wheel

- Belt Problems and Drive Misalignment

- Air Flow and Air Turbulence Problems

- Fan Bent Shaft Condition

- Fan Surge Condition