Site balancing

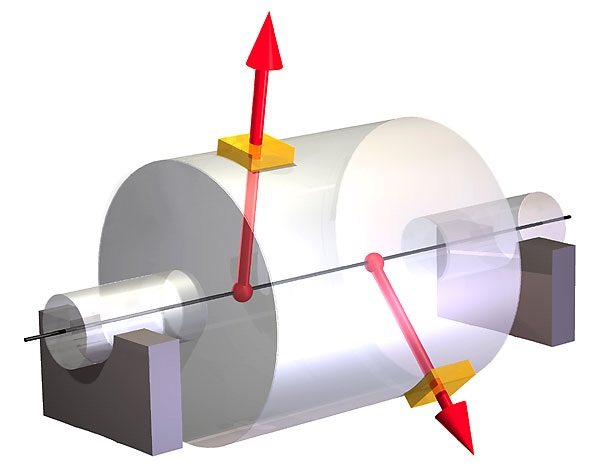

It is often time consuming and expensive to remove fans and other plant from site when there is found to be vibration issues due to out of balance. PPTOTAL have all the necessary skills, personnel and equipment to carry out the site balancing process quickly and efficiently.

Reasons for Balancing

A rotor can have material buildup (dirt or grease on fans) or material loss (erosion on material moving fans), bearing wear that affects the center of rotation (severely worn parts need to be replaced before balancing), shaft distortion due to residual stress relaxation, structural changes, or speed increases. This causes vibration that will result in premature failure of bearings and other machine components. It can also result in cracks and other structural defects that could cause catastrophic failure.

The purpose of dynamic balancing is to reduce centrifugal forces that cause damage or discomfort to people near the vibration